Loctite® Compounds - Aggregate

Backing Compound

In the Aggregate industry, backing compound is used in cone crushers and grinding mills to fill gaps in wear liners and backing plates. This pourable epoxy compound allows you to get the full life of your equipment, by providing positive support of liners and preventing cavitation.

Wearing Compound

Brushable and trowelable, wearing compounds are used throughout the Aggregate and Cement processes inside chutes, feeders, hoppers, pumps, and pipes. This ceramic epoxy offers abrasion and impact resistance superior to that of ceramic tile, protecting your equipment and reducing downtime.

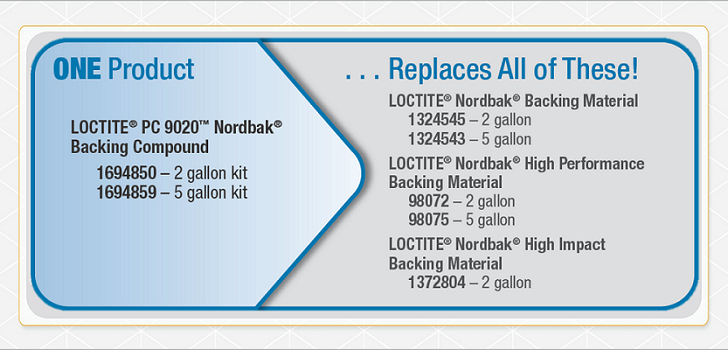

LOCTITE® PC 9020™ – Backing Compound

LOCTITE® PC 9020™ is a blue, 2-part epoxy system for backing wear metal in gyratory and cone crushers made to eliminate the formation of gaps between backing and liners or support structures, allowing for fast return to service. Under typical dry service temperatures of -30 to 105°C (-20 to 220F), the product eliminates the needs for traditional melting or special equipment, and has low water absorption and high volumetric stability. This one product will deliver the performance you need with the increased worker safety and convenience you want.

Available Size Options

Advantages:

• Color changing technology to assure product is fully mixed

• Higher compressive strength

• Higher impact resistance

• Low Odor

• Low Shrinkage

Loctite® PC 9313 – Wearing Compound

LOCTITE® PC 9313 is a gray, 2-part, rubber modified epoxy. With impact resistance superior to ceramic tile, it is recommended for lining and protecting troughs, hoppers, discharge chutes, vibrating feeders, and other processing equipment that is exposed to both abrasion and impact.

Available Size Options

Advantages:

• Cures to ceramic hardness – Resists sliding abrasive wear

• Won’t sag or shrink – Conforms to overhead and irregular surfaces, application versatility

• Renews worn surfaces fast – Reduces downtime

• Impact resistant – Resists mild impact at 45° angles

• Offers the wear resistance properties of an epoxy along with impact resistance

• Trowelable

DISCLAIMER: The above content is provided by the supplier. Applied® does not guarantee the accuracy or timeliness of the content.

The above content is provided “AS IS”, AND ANY AND ALL EXPRESS AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS ARE HEREBY EXCLUDED.

All warranties, if any, are solely from the supplier.

Find a Service Center

Find a Service Center