MORE REASONS YOU SHOULD SWITCH TO SKF COOPER SPLIT-TO-THE-SHAFT ROLLER BEARINGS:

COMMON INDUSTRIES:

- Designed to reduce:

– Installation

– Changeover

– Inspection time - Superior seals

- Compensation for misalignment

- Shaft protection

- Minimized resistance and equipment stress for dynamic axial expansion

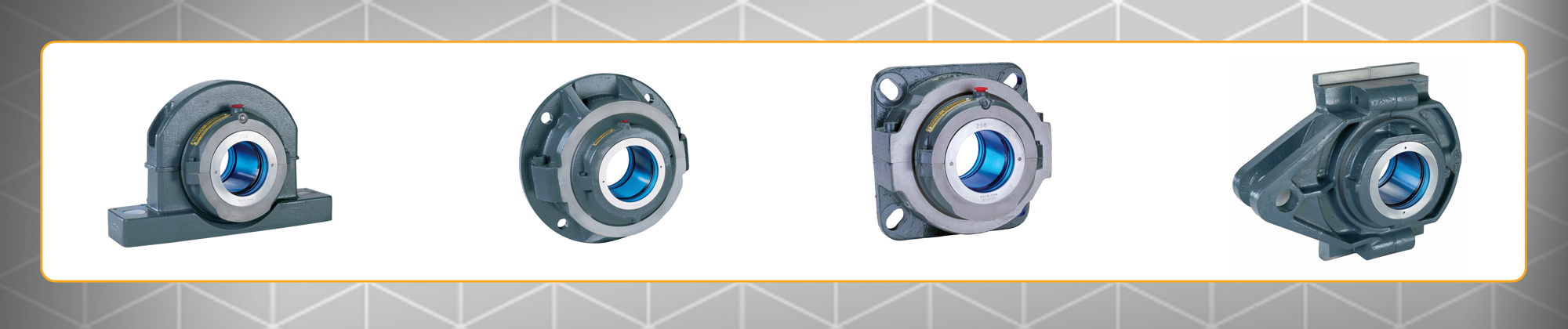

- Comprehensive range of mountings

FEATURES:

- ✓ Cement

- ✓ Food & beverage

- ✓ Forest products / Pulp & paper

- ✓ Grain & sugar

- ✓ Iron & steel

- ✓ Oil & gas

- ✓ Power generation

- ✓ Water treatment

Find a Service Center

Find a Service Center