Features:

- Reliable – clean – automatic lubrication on a 24-hour basis

- High-capacity – compact size for easy installation in confined areas

- Ideal for hard-to-reach Locations – with time settings of up to 12 months

- Can be deactivated by operator – at any time

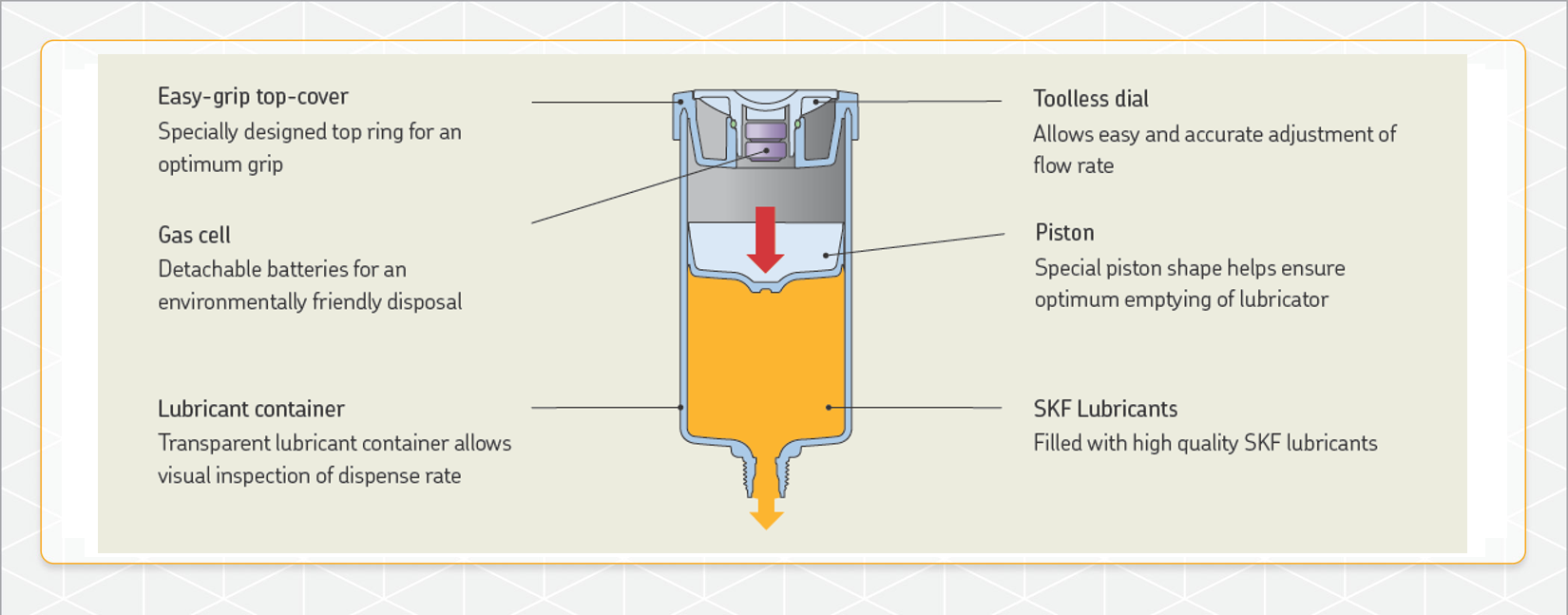

- Filled with SKF lubricants

Applications:

- ✓ Bearings lubricated through a grease fitting

- ✓ Bearings in remote – hard-to-reach locations

- ✓ Fans – motors – conveyors – process equipment – elevators

- ✓ Chains and machine tool slides

Find a Service Center

Find a Service Center