BENEFITS OF LOCTITE® MRO WORKSHOP TRAININGS:

- In-house or

off-site - Hands-on training

- Covers all trades

- Tool kits issued

- Review common failure causes and prevention

- Training materials supplied

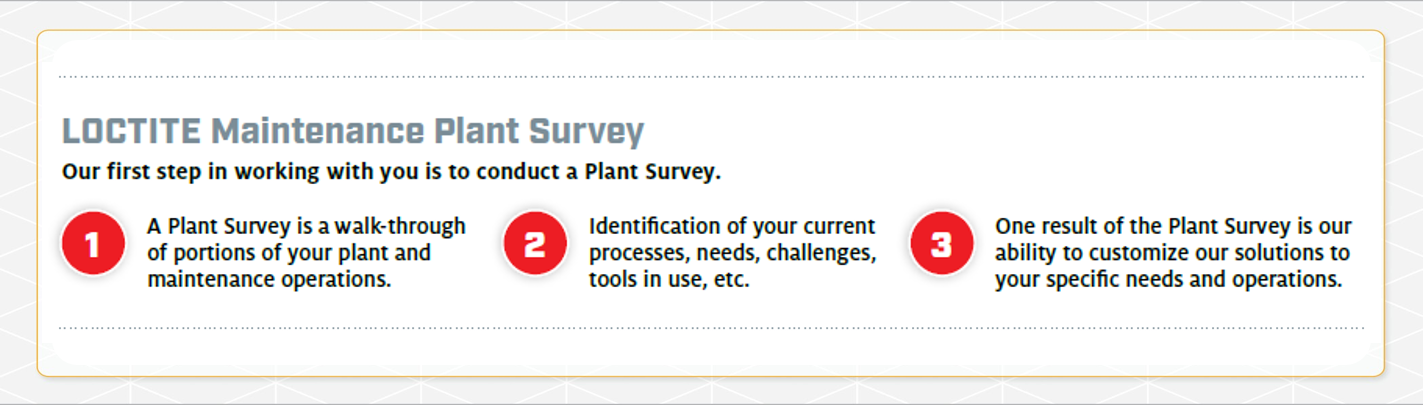

- Workshop can be tailored to meet your needs through a plant tour and pre-survey

- In-plant follow-up

MRO Workshop Training Program Overview

Read more on maintenance workshop features and details.

Download Pdf

Find a Service Center

Find a Service Center